Frying Control

Our fully automatic potato chips line has Multi-oil inlets which ensures steady oil flow, clears the infeed area, and allow quick temperature adjustments for feed changes.

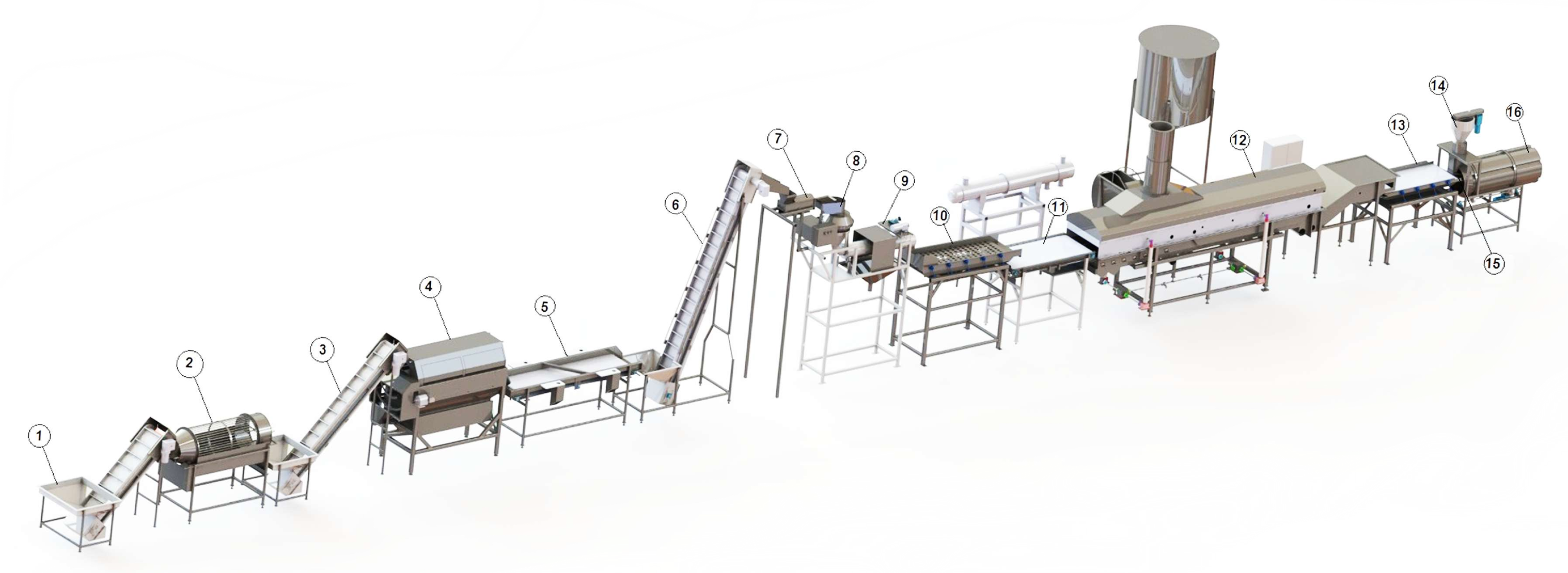

The Fully Automatic Potato Chips Line is A Continuous Processing System Which is Suitable for Processing of Potato.

Unique designed Programmable Logic Control (PLC) system controls multiple machines and process functions, pre-programmed product menus, and complete data management at the touch of a single screen touch enabled display screen. The PLC control panel is customized and designed specifically for the entire processing line

Our fully automatic potato chips line has Multi-oil inlets which ensures steady oil flow, clears the infeed area, and allow quick temperature adjustments for feed changes.

Circulating oil keeps fines in suspension for efficient removal. Every minute 100% of the system oil volume passes through drum filter to remove 100% product particles for the highest oil & product quality.

Low oil volume and rapid turnover ensure a fresh product with an extended shelf life.

Our Innovatively designed air knife removes excess water from washed slices. This reduces surface moisture before frying, lowering energy consumption and extending the shelf life of the edible oil.

Our compact design ensures cost-efficient operations by minimizing space, energy, and water usage.

| MODEL | FACL-300 | FACL-500 | FACL-1000 |

|---|---|---|---|

| Output | 300 Kg/Hr | 500 Kg / Hr. | 1000 Kg / Hr |

| Edible Oil Holding Capacity | 1000 Ltr. | 1650 Ltr. | 3000 Ltr. |

| Power Required With Blancher | 67 HP | 86 HP | 120 HP |

| Power Required Without Blancher | 50 HP | 64 HP | 100 HP |

| Water Required | 2100 Ltr./Hr | 3600 Ltr./Hr | 6100 Ltr./Hr |

| Floor Space | 3500 Sq ft | 4200 Sq ft | 5500 Sq ft |

| Length of the Line | 150 ft | 165 ft | 170 ft |

| Material of Construction | AISS-304 Grade | AISS-304 Grade | AISS-304 Grade |

| Wood Consumption | 270-280 Kg/Hrs. | 450-470 Kg/Hrs. | 900-950 Kg/Hrs. |

| Pellets Consumption | 190-220 kg/Hrs. | 350-360 Kg/Hrs. | 700-750 KG/Hrs. |