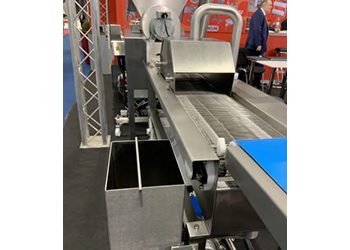

The EconoRobe applies high quality coverage of numerous batters and marinades for a wide variety of products. The ease of switching batters between production runs increases efficiencies and productivity.

As the product travels along the conveyor, it is fully submerged into a tank of batter. A weighted top conveyor assists to channel the product through the tank, ensuring the product remains immersed in the batter/marinade.

As the product leaves the tank an air knife removes excess batter, presenting the product for the next processing or packaging stage. A variable speed dial enables the operator to increase/decrease the speed of the belt as required.

Product Features:

- Simple to operate and maintain

- Variable speed control

- Suitable for tempura style batters