Pre Heater

Indigenously developed pre heater ensures maximum expansion & minimum oil absorption inspite of variation in shape, size & moisture of raw pellets.

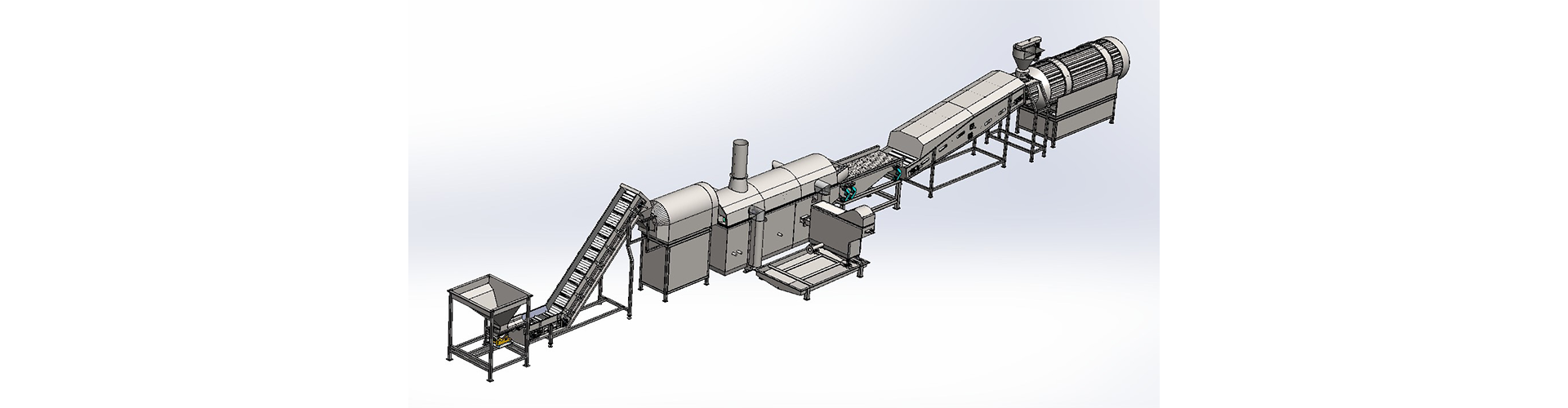

Our Pellet Frying Line includes various parts such as a Pellet Feeder, Pellet Preheater, Fryer, Cooling cum De-oiling conveyor, seasoning drum etc. which work together to create the perfect fried pellets. It is easy to operate and maintain and is built to last. We also provide ongoing support and maintenance services to ensure that your equipment stays in top condition.

If you’re looking for a reliable and efficient frying solution for your snack pellet production business , look no further than our Fully Automatic Pellet Frying Line. Contact us today to learn more about how we can help you fry your pellets to perfection!

Indigenously developed pre heater ensures maximum expansion & minimum oil absorption inspite of variation in shape, size & moisture of raw pellets.

Specially engineered, step take out belt & two step De-oiling belt ensures optimal oil removal from the product.

Circulating oil keeps fines in suspension for efficient removal. Every minute 100% of the system oil volume passes through drum filter to remove product particles for the highest oil & product quality.

Low oil volume and rapid oil turnover assure fresh product with a long shelf life. Optimal level is automatically maintained.

Compact design results into cost efficient operations by reducing space & energy usage.

| Model | PFL - 500 | PFL - 1000 | PFL - 2000 |

|---|---|---|---|

| Output | 500 Kg/ Hr | 1000 Kg/ Hr | 2000 Kg/ Hr |

| Edible Oil Holding Capacity | 500 Ltrs | 800 Ltrs | 1200 Ltrs |

| Power Required With Blancher | 20 Hp | 25 Hp | 30 Hp |

| Floor Space | 1500 Sq. Ft. | 1800 Sq. Ft. | 2000 Sq. Ft. |

| Length Of the Line | 60 Ft | 65 Ft | 65 Ft |

| Material of Construction | AISS-304 Grade SS | AISS-304 Grade SS | AISS-304 Grade SS |